真空包裝

真空包裝真空成型真空包裝是一種包裝技術,它可以將產品放入塑料薄膜中,然後將空氣抽出,形成一個密封的包裝。這種包裝可以保護產品免受氧氣、濕度和污染物的影響,延長產品的保質期。

真空包裝真空成型真空包裝是一種包裝技術,它可以將產品放入塑料薄膜中,然後將空氣抽出,形成一個密封的包裝。這種包裝可以保護產品免受氧氣、濕度和污染物的影響,延長產品的保質期。

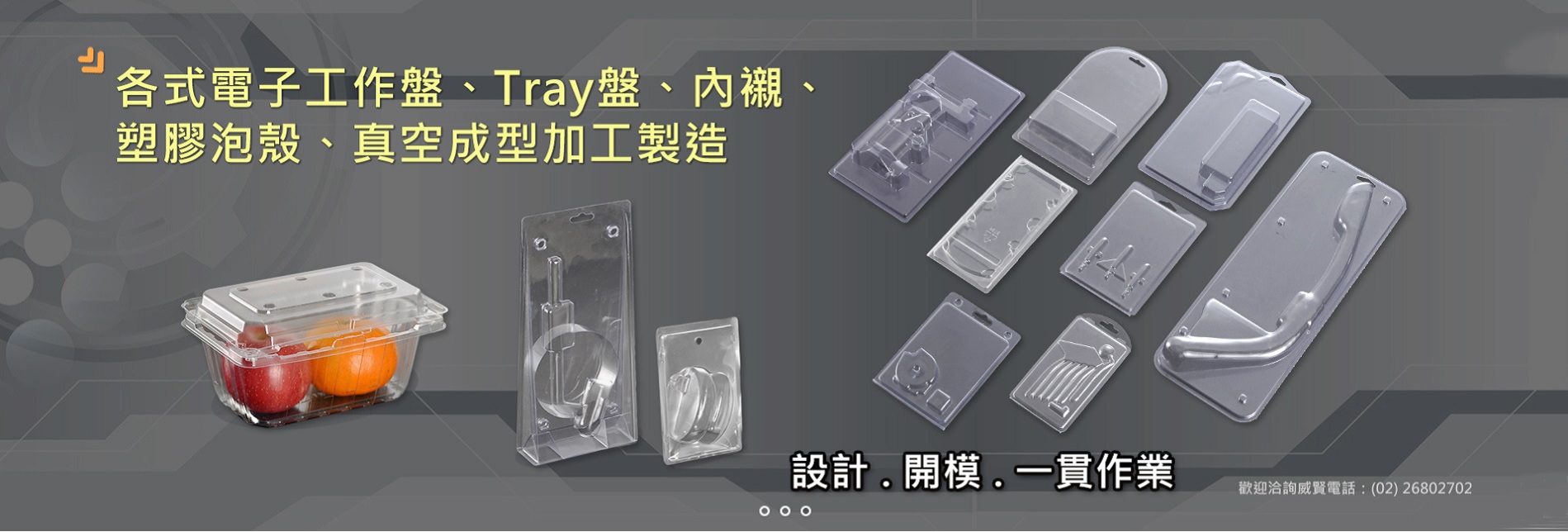

真空成型真空包裝通常使用熱塑性塑料,如聚乙烯(PE)、聚丙烯(PP)或聚乙烯醇(PVA)等,這些塑料可以通過加熱和加壓的方式,變成適合包裝的形狀。真空成型真空包裝適用於各種產品,如食品、醫療器械、電子產品、化妝品等。

真空包裝有許多優點,如保護產品、提高產品的外觀、延長保質期、減少污染、方便運輸等。但是,它也有一些缺點,如成本較高、需要專業設備和技能、對環境的影響等。因此,在使用真空成型包裝時,需要根據具體情況進行綜合考慮。 真空包裝

真空包裝

真空包裝的過程通常包括以下步驟:首先將熱塑性塑料片加熱軟化,然後將其置於模具上,通過負壓或正壓的方式將空氣抽出或壓縮,使塑料片貼合模具表面,形成所需形狀。最後,冷卻後取出產品,完成真空成型的過程。

真空包裝的應用十分廣泛,從食品包裝、電子產品外殼到汽車零部件等都有使用。相對於傳統的包裝方式,真空成型包裝可以更好地保護產品的質量,並且可以提高產品的可見性和質感。此外,真空成型包裝還可以適應各種形狀和尺寸的產品,具有很強的靈活性和多樣性。

然而,真空包裝也存在著一些問題,例如塑料浪費和環境影響等。塑料浪費是指在成型過程中,未能有效利用原材料而造成的浪費;而環境影響主要表現在成型過程中產生的廢氣和廢水等對環境造成的負面影響。因此,為了避免這些問題,需要通過優化製程和使用可持續的材料來降低成本和環境風險。

在真空成型真空包裝過程中,選擇適合的原材料是非常重要的。常用的材料有聚乙烯、聚丙烯、聚苯乙烯、聚碳酸酯等。這些材料具有不同的物理和化學性質,並且適用於不同的產品。

另外,在真空成型包裝中,還需要注意一些重要的技術要點。例如,模具的設計和製造需要根據產品的形狀和尺寸進行優化,以保證產品的成型效果和產品的質量。此外,適當的真空度和成型溫度也是關鍵因素,這些參數需要根據產品的材料和形狀進行調整和控制,以達到最佳的成型效果。

真空包裝最後,真空成型包裝的應用對環境和可持續性也存在一定的挑戰。為了解決這些問題,可以採取一些措施,如使用可回收的材料、優化成型工藝、採用可再生能源等。同時,還可以通過政策和法規的支持,推動真空成型包裝產業向更加環保和可持續的方向發展。

真空包裝最後,真空成型包裝的應用對環境和可持續性也存在一定的挑戰。為了解決這些問題,可以採取一些措施,如使用可回收的材料、優化成型工藝、採用可再生能源等。同時,還可以通過政策和法規的支持,推動真空成型包裝產業向更加環保和可持續的方向發展。

除了環境和可持續性方面的挑戰,真空成型包裝還存在其他一些問題和限制。例如,真空成型包裝的成本較高,需要投資較多的設備和技術,這對中小型企業來說可能是一個難題。此外,真空成型包裝也存在一些形狀複雜的產品難以成型的問題,這需要通過優化設計和製造工藝來解決。

另外,真空成型包裝還需要考慮一些產品特性的問題,如食品包裝需要考慮到食品的安全和衛生等方面。同時,真空成型包裝也需要考慮到產品的運輸和儲存等問題,以確保產品的完整性和品質。

總體而言,真空成型包裝是一種廣泛應用的包裝技術,可以有效保護產品,提高產品的質量和價值。然而,在使用真空成型包裝時需要充分考慮各種因素,如材料選擇、製程優化、環境影響等,以確保產品的質量和生產效率。

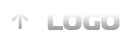

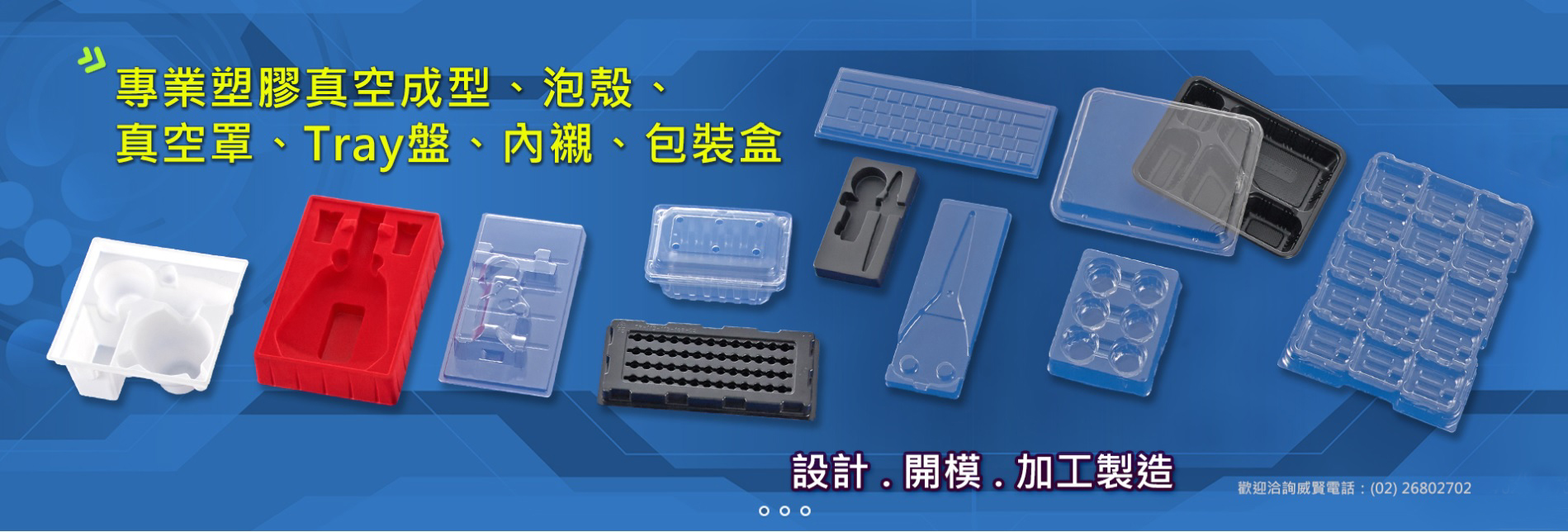

真空包裝專業的真空包裝真空成型加工製造廠,可以客製化塑膠包裝盒,提供設計美觀、衛生、安全的外盒。材料包括PET、PS、PP和PVC,可以製作收納盒、包裝盒、內襯、置物盒、抗靜電盒、汽車、機械五金盒、運動器材、體育用品包裝盒、食品容器盒、玩具、禮品、贈品包裝盒、通信設備零件、對折盒、三折盒、手工盒、圓筒盒等產品。

真空包裝專業的真空包裝真空成型加工製造廠,可以客製化塑膠包裝盒,提供設計美觀、衛生、安全的外盒。材料包括PET、PS、PP和PVC,可以製作收納盒、包裝盒、內襯、置物盒、抗靜電盒、汽車、機械五金盒、運動器材、體育用品包裝盒、食品容器盒、玩具、禮品、贈品包裝盒、通信設備零件、對折盒、三折盒、手工盒、圓筒盒等產品。

本廠擁有30多年的專業真空成型製造經驗,可以提供高品質的產品包裝盒、植絨內襯、封口罩、真空包裝、透明盒等。他們的產品可以廣泛應用於各種行業和場合,例如食品、電子、汽車、機械、運動器材、玩具、禮品、贈品等。

如果您需要客製化的塑膠包裝盒或其他產品,您可以聯繫這家專業的真空成型加工製造廠,提供您所需的產品和服務。他們將會提供專業的設計和製造,並確保產品的質量和交期。

真空包裝、真空成型加工製造還可以提供一系列的加工和製造服務,例如模具設計和製造、塑膠成型加工、封口、切割、表面處理等。他們擁有先進的設備和技術,可以根據客戶的需求和要求,提供高品質、高精度的加工和製造服務。

注重產品的環保和可持續性。使用的材料和製造工藝都符合環保要求,並且通過ISO 14001環境管理體系認證,確保產品的環保性能和可持續性。

如果您需要塑膠包裝盒、真空包裝、或其他產品的設計和製造服務,可以考慮專業的真空成型加工製造廠。我們擁有豐富的經驗和先進的技術,可以為客戶提供高品質、高效率的服務,並且注重環保和可持續性。

此外,、真空包裝還重視客戶的需求和反饋,不斷進行創新和改進,以滿足客戶不斷變化的需求。他們還可以根據客戶的要求進行快速樣品製作,以確保客戶對產品的設計和質量有更直觀的了解和評估。

總之,真空包裝提供了全面的設計和製造服務,從產品設計到製造和包裝,都能夠為客戶提供一站式的服務。他們擁有豐富的經驗和先進的技術,注重環保和可持續性,並且重視客戶的需求和反饋,不斷進行創新和改進。如果您需要塑膠包裝盒、真空包裝、或其他產品的設計和製造服務,真空包裝是一個值得考慮的選擇。

真空包裝此外,真空包裝還可以為客戶提供定制化的解決方案,根據客戶的特定需求和要求,進行量身設計和製造,以滿足客戶的具體需求。擁有豐富的經驗和技術,可以為客戶提供專業的建議和意見,以確保產品的設計和製造符合客戶的要求和標準。

真空包裝此外,真空包裝還可以為客戶提供定制化的解決方案,根據客戶的特定需求和要求,進行量身設計和製造,以滿足客戶的具體需求。擁有豐富的經驗和技術,可以為客戶提供專業的建議和意見,以確保產品的設計和製造符合客戶的要求和標準。

此外,真空包裝可以為客戶提供短交期和小批量生產的服務,以滿足客戶快速上市的需求。他們擁有高效的生產線和靈活的製造模式,可以在短時間內生產高品質的產品,並且可以根據客戶的需求進行靈活的生產和調整,以確保客戶的需求得到及時滿足。

總之,真空包裝加工製造提供了全面的設計和製造服務,可以為客戶提供專業的建議和定制化的解決方案,並且可以提供短交期和小批量生產的服務,以滿足客戶快速上市的需求。如果您需要塑膠包裝盒、真空包裝、或其他產品的設計和製造服務,我們的真空包裝是一個值得信賴的選擇。

Vacuum forming Vacuum packaging is a packaging technology that puts products into plastic films and then extracts the air to form a sealed package. This packaging protects the product from oxygen, humidity and contaminants, extending the shelf life of the product.

Vacuum forming vacuum packaging usually uses thermoplastic plastics, such as polyethylene (PE), polypropylene (PP) or polyvinyl alcohol (PVA), etc. These plastics can be transformed into a shape suitable for packaging by heating and pressure. Vacuum forming vacuum packaging is suitable for various products, such as food, medical equipment, electronic products, cosmetics, etc.

Vacuum packaging has many advantages, such as protecting products, improving product appearance, extending shelf life, reducing pollution, and facilitating transportation, etc. However, it also has some disadvantages, such as higher cost, need for professional equipment and skills, impact on the environment, etc. Therefore, when using vacuum forming packaging, comprehensive considerations need to be made based on specific circumstances. vacuum packaging

The vacuum packaging process usually includes the following steps: first heat and soften the thermoplastic sheet, then place it on the mold, and extract or compress the air through negative or positive pressure to make the plastic sheet fit the mold surface and form the desired shape. shape. Finally, the product is taken out after cooling to complete the vacuum forming process.

Vacuum packaging is used in a wide range of applications, ranging from food packaging, electronic product casings to automobile parts. Compared with traditional packaging methods, vacuum forming packaging can better protect the quality of the product and improve the visibility and texture of the product. In addition, vacuum forming packaging can also adapt to products of various shapes and sizes, with strong flexibility and diversity.

However, there are also some problems with vacuum packaging, such as plastic waste and environmental impact. Plastic waste refers to the waste caused by the failure to effectively utilize raw materials during the molding process; the environmental impact is mainly reflected in the negative impact on the environment such as waste gas and waste water generated during the molding process. Therefore, in order to avoid these problems, costs and environmental risks need to be reduced by optimizing processes and using sustainable materials.

In the vacuum forming and vacuum packaging process, it is very important to choose suitable raw materials. Commonly used materials include polyethylene, polypropylene, polystyrene, polycarbonate, etc. These materials have different physical and chemical properties and are suitable for different products.

In addition, there are some important technical points that need to be paid attention to in vacuum forming packaging. For example, the design and manufacturing of molds need to be optimized according to the shape and size of the product to ensure the molding effect of the product and the quality of the product. In addition, appropriate vacuum degree and molding temperature are also key factors. These parameters need to be adjusted and controlled according to the material and shape of the product to achieve the best molding effect.

Vacuum packaging Finally, the application of vacuum forming packaging also poses certain challenges to the environment and sustainability. In order to solve these problems, some measures can be taken, such as using recyclable materials, optimizing molding processes, using renewable energy, etc. At the same time, the vacuum forming packaging industry can also be promoted to develop in a more environmentally friendly and sustainable direction through the support of policies and regulations.

In addition to environmental and sustainability challenges, vacuum formed packaging also presents several other issues and limitations. For example, the cost of vacuum forming packaging is higher and requires investment in more equipment and technology, which may be a problem for small and medium-sized enterprises. In addition, vacuum forming packaging also has the problem that some products with complex shapes are difficult to form, which needs to be solved by optimizing the design and manufacturing process.

In addition, vacuum forming packaging also needs to consider some product characteristics. For example, food packaging needs to consider food safety and hygiene. At the same time, vacuum forming packaging also needs to consider issues such as product transportation and storage to ensure product integrity and quality.

Overall, vacuum forming packaging is a widely used packaging technology that can effectively protect products and improve product quality and value. However, various factors need to be fully considered when using vacuum forming packaging, such as material selection, process optimization, environmental impact, etc., to ensure product quality and production efficiency.

A professional vacuum packaging and vacuum forming processing and manufacturing factory, we can customize plastic packaging boxes and provide outer boxes with beautiful designs, hygiene and safety. Materials include PET, PS, PP and PVC, which can be used to make storage boxes, packaging boxes, linings, storage boxes, anti-static boxes, automobiles, machinery hardware boxes, sports equipment, sporting goods packaging boxes, food container boxes, toys, gifts, Gift packaging boxes, communication equipment parts, half-fold boxes, three-fold boxes, handmade boxes, cylindrical boxes and other products.

Our factory has more than 30 years of professional vacuum forming manufacturing experience and can provide high-quality product packaging boxes, flocking linings, sealing masks, vacuum packaging, transparent boxes, etc. Their products can be widely used in various industries and occasions, such as food, electronics, automobiles, machinery, sports equipment, toys, gifts, premiums, etc.

If you need customized plastic packaging boxes or other products, you can contact this professional vacuum forming processing manufacturer to provide the products and services you need. They will provide professional design and manufacturing and ensure product quality and delivery.

Vacuum packaging, vacuum forming processing and manufacturing can also provide a series of processing and manufacturing services, such as mold design and manufacturing, plastic molding processing, sealing, cutting, surface treatment, etc. They have advanced equipment and technology to provide high-quality, high-precision processing and manufacturing services according to customer needs and requirements.

Pay attention to the environmental protection and sustainability of products. The materials and manufacturing processes used comply with environmental requirements and have passed ISO 14001 environmental management system certification to ensure the environmental performance and sustainability of the product.

If you need design and manufacturing services for plastic packaging boxes, vacuum packaging, or other products, you can consider a professional vacuum forming processing factory. We have rich experience and advanced technology to provide customers with high-quality, efficient services and pay attention to environmental protection and sustainability.

In addition, vacuum packaging also attaches great importance to customer needs and feedback, and constantly innovates and improves to meet the changing needs of customers. They can also perform rapid sample production according to customer requirements to ensure that customers have a more intuitive understanding and evaluation of the product's design and quality.

In short, vacuum packaging provides comprehensive design and manufacturing services, from product design to manufacturing and packaging, able to provide customers with one-stop service. They have rich experience and advanced technology, pay attention to environmental protection and sustainability, and value customer needs and feedback, constantly innovating and improving. If you need design and manufacturing services for plastic packaging boxes, vacuum packaging, or other products, vacuum packaging is an option worth considering.

Vacuum Packaging In addition, vacuum packaging can also provide customers with customized solutions, tailor-made design and manufacturing according to the specific needs and requirements of customers to meet their specific needs. With rich experience and technology, we can provide customers with professional suggestions and opinions to ensure that the design and manufacturing of products meet customer requirements and standards.

In addition, vacuum packaging can provide customers with short delivery times and small batch production services to meet customers' needs for rapid market launch. They have efficient production lines and flexible manufacturing models that can produce high-quality products in a short time, and can flexibly produce and adjust according to customer needs to ensure that customer needs are met in a timely manner.

In short, vacuum packaging processing and manufacturing provides comprehensive design and manufacturing services, can provide customers with professional advice and customized solutions, and can provide short delivery and small batch production services to meet customers' needs for rapid market launch. If you need plastic packaging boxes, vacuum packaging, or other product design and manufacturing services, our vacuum packaging is a trustworthy choice.